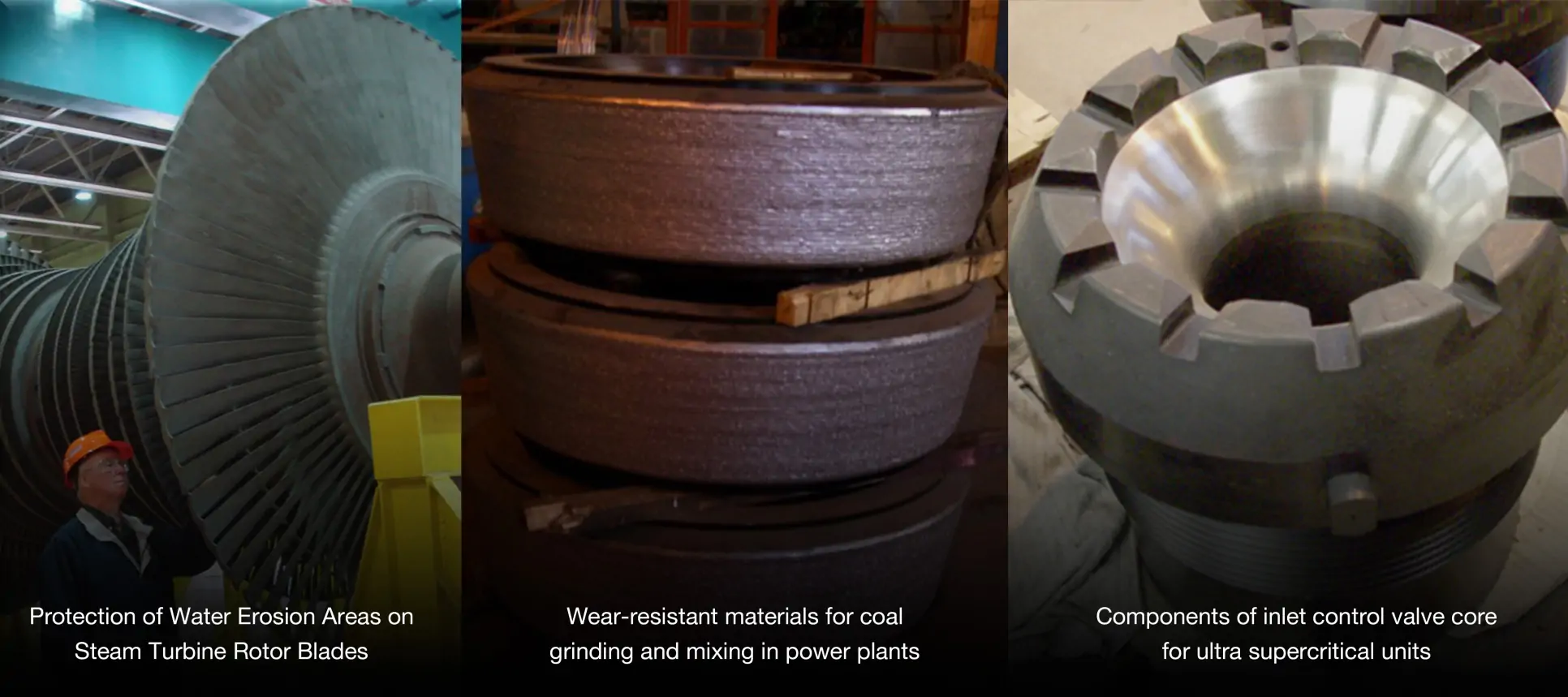

The power industry has always been one of the key areas of concern for global materials scientists. With the advancement of technology, in order to pursue higher work efficiency, power generation equipment is facing more demanding working environments than before, including higher working temperatures and pressures. Manufacturers need to provide wear-resistant protection for core components while ensuring maximum safety, in order to extend equipment service time and achieve optimized and flexible power production. These components must have the ability to resist wear, erosion, cavitation, fatigue, and corrosion at high temperatures. Bzzalloy is a global provider of solutions for wear, high temperature, and corrosion issues. It is also a world-renowned manufacturer of high-temperature resistant components, making us a partner with many globally renowned manufacturers in the power generation industry. Stellite and JK series alloy materials, due to their superior high-temperature and cavitation resistance, have been widely used by customers in the power industry to protect the sealing surfaces of various valves in high-temperature steam circuits. At the same time, we also provide various casting and coating products for customers in the power industry. Our Starweld plasma surfacing system and Jet-Kote supersonic spraying system are also prioritized for manufacturing high-quality coatings in the power industry.

Typical Applications